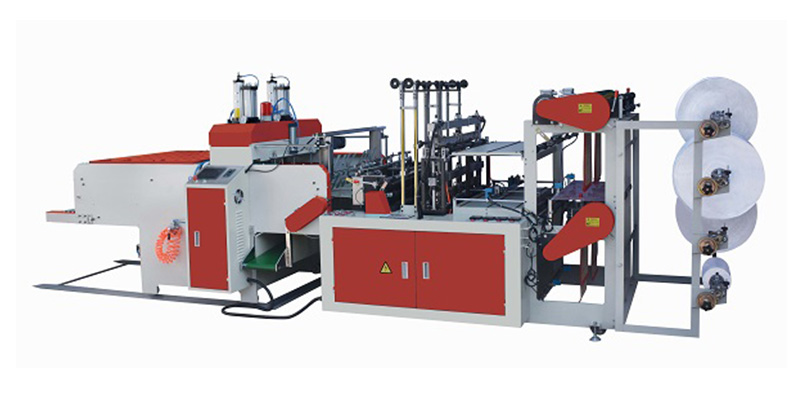

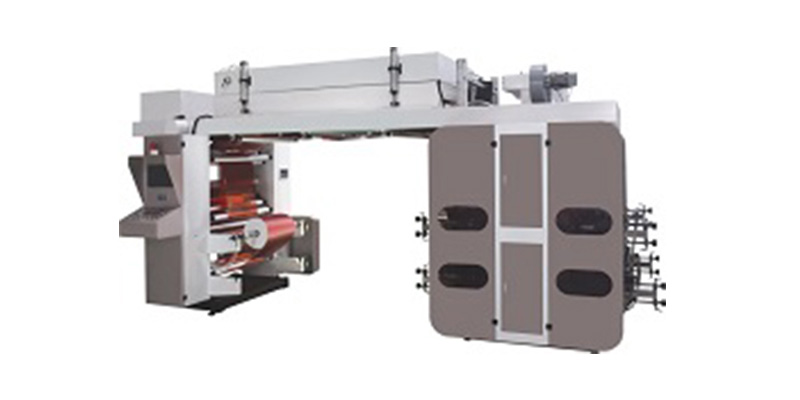

The Main difference of hot cutting bag making machine and cold cutting bag making machine

1.The difference in bag type

The sealing edge of the bag made by the hot cutting bag making machine will have some folds and the bottom can not be opened; The cold cutting bag making machine makes the bag edge flat bottom can be opened.

Hot cutting bag making machine is to cut immediately after sealing; Cold cutting bag making machine is to cut after sealing, and the sealing incision of the cold cutting bag will be more firm than that of the hot cutting bag.

The main difference is hot cutting machine is to do plastic shopping bag, the cold cutting bag making machine can do shopping bag and flat bag both.

2.Machine Output and speed

The speed of the hot cutting bag making machine can be more 220 pcs/min for a line, and the speed of the cold cutting bag making machine can be 120 pcs/min for a line. The hot cutting bag making machine from Ruian Tplast Machine Co.,Ltd can do 480pcs to 560pcs/min, cold cutting bag making machine can do 240-480pcs/min bags.

3.Printing bag line

Hot cutting bag making machine have two photocell that can make two lines with printed bags at the same time; Cold cutting bag making machine has only one photocell, which can make a line to print the bag (If you need to make two lines, we can customize the double servo bag making machine).

So if you want to make printed bags and high speed requirements, you can choose to buy a hot cutting bag making machine, and if you do non printing bags and have a limited budget, you can choose a cold cutting bag making machine.

English

English Français

Français Español

Español