3 Layer Blown Film Extrusion Machine Taiwan

3 layer blown film extrusion machine is used for heavy packaging like the fresh fruit, meat, fresh milk and beverages ect. The screw and barrel use use taiwan design. there are 2 feeding design and deep mixing parts, So there is big pressure inside of barrel.

3 Layer Blown Film Extrusion Machine Use:

3 layer blown film extrusion machine lines can be blown continuous 0.02-0.15mm in the thickness packaging films, from LDPE, HDPE, LLDPE, MLLPE, by horizontal extrusion up blown. The film has good in solution, for instance holding temperature, anti-humid, anti-breeze, anti-rain, anti-roust, insulation oxygen, oil resistive, and so used for light and heavy-duty packaging, for example fresh fruits, meat-feeding, salt vegetables, fresh milk, drink.

3 Layer Blown Film Extrusion Machine Main Technical Variables:

|

Model |

SJ-50*3/RG1000 |

SJ-55*3/RG1200 |

SJ-60*3/RG1800 |

SJ-70*3/RG2500 |

|

Screw Diameter(mm) |

45/50/45 |

50 /55/50 |

60/65/60 |

65 /70/65 |

|

Screw Ratio(L/D) |

30:1 |

30:1 |

30:1 |

30:1 |

|

Screw Speed(r/min) |

110 |

110 |

110 |

110 |

|

Power of Main Motor(kw) |

11/15/11 |

15/18.5/15 |

22/30/22 |

30/37/30 |

|

Range of Die(mm) |

¢200 |

¢300 |

¢450 |

¢650 |

|

single-sided Thickness of Film(mm) |

0.015-0.15 |

0.02-0.15 |

0.03-0.20 |

0.05-0.20 |

|

Max.Folding Width of Film(mm) |

1000 |

1200 |

1800 |

2500 |

|

Max output |

130kg/h |

150kg/h |

180kg/h |

250kg/h |

|

Electric Total Capacity(kw) |

85 |

95 |

120 |

180 |

|

Weight of Machine(kg) |

5500 |

6500 |

7500 |

9800 |

|

Overall Dimensions (L*W*H)(m) |

6.6*2.8*5.5 |

6.8*3*6 |

7*3.2*8.5 |

8.5*5*10.5 |

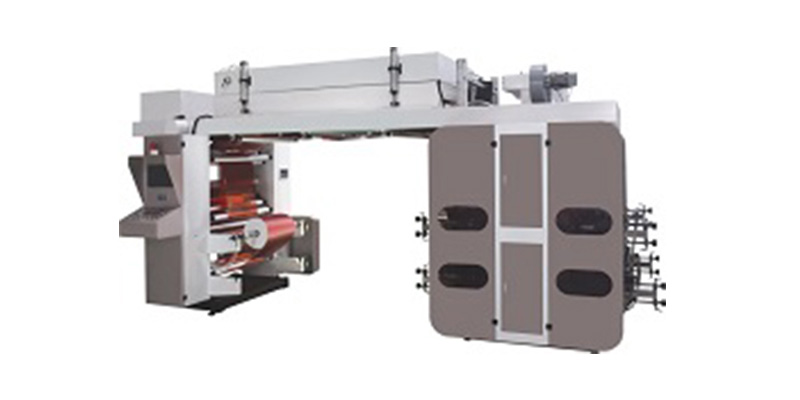

3 Layer Blown Film Extrusion Machine Main Parts Parameter and pictures:

Screw: Copied from Taiwan, Bimetal

1.Material of screw and barrel: 38CrMoAlA

2.Material Element Analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3.Hardness of tempering: HB260-290

4.Depth of nitriding: 0.4-0.7mm

5.Hardness of surface: HV900-1050

6.Roughnessof surface:Ra0.32

7.Linearity of screw: 0.015mm/m

8.Bimetal screw: Bimetal layer on the screw thread

9.Hardness of bimetal layer: HRC58-62

10. Depth of bimetal layer: 2-3mm

11. Bimetal layer elements: Fe, Ni, Wc, B, C, Cu, ect

Main motor: Siemensbrand

1, Runing Speed: 1400rpm,

2, Motor power: , 380V, 3phase. Pwoer can be changed according yours

3, Motor Life: more 10 years.

Gearbox:

1, Fucntion: reduce the speed of transfer.

2, Speed rate: 10:1

3, Gear: Hard surface type, high quality.

4, Lubrication oil for transfering

5: Low noise and longer life

Heater: Ceramic heater fucntion:

1, Heating faster than stainless heater.

2, Life is longer to 5 years.

3, Keep hot inside is longer than stainless, save power.

4, High quality ceramic and heating wire Inside.

Cover: Stainless cover:

1, Separate stainless cover to control heater better and save the power consuption.

2, Separate blower on stainless cover.

3, Nice outlook for stainess cover

4, High speed blower to cool barrel.

Rotary Die head: Taiwan design high speed die head:

1, #45 steel stronger

2, Surface treatment,which make film more transparent

3,bigger size than normal, which improve the output of machines

Fast screen changer: Fast screen changer:

1, Save worker working

2, Never leakage for materails

3, Easily to change the fiter, save time

Double vent air ring:

1, two lip to cool the film, it is faster than one lip.so it can improve the output of machine

2, it can do HDPE and LPDE film.

Electric parts: Omron Temperature controller:

1, Digital show

2, Accurate temperature controlling for 3 centigrade

Controller box and LG inverter:

1, LG inveter to adjsut the speed of all motor, which can save the power consumption, protect the motor working and more 10 years life, Easy to adjust the inverter.

Double Rewinder:

1, air shaft: save manual working,improve the working efficency.

2, Inverter can be longer life and protect the motor running

3, PLC Control.

4, Automatic Changer.

Whole Machine

3 Layer Blown Film Extrusion Machine Characteristics:

1.Die head is lauer type spiral mandrel, continuous 360, rotation.

2. Screen pack changer Design is rational convenience, reliable, safe in operation.

3. Various functional parts may be installed to the lies, such as length counting device, vertical cutting device, cooling water row pipe, film spreading roller, scrap collecting device.

> What is bag making machine?

A bag making machine is a machine that helps in the manufacturing different type bags. The T-shirt bag making machine is used for making the T-shirt bag. It can cut ...

> Side Sealing Bag Making Machine Features

Our Side sealing bag making machine have the following features:The unwinding part is controlled by the air cylinder which control the rubber roller, so that it is o...

> Loading Bag making machine and film blowing machine to Côte d'Ivoire

Today we loading two container to Côte d'Ivoire. The customer bough 4 sets film blowing machines, 4 sets bag making machine and 1 set heavy duty bag making machine a...

> Loading Bag making Machine to Colombia

We are happy to load the one set bottom sealing bag making machine, one set side sealing bag making machine and granulator to Colombia Customer today. It is very nic...

> Heavy Duty Bag Making Machine is praised by Mexico Customer.

Today our professional Customer Mr.Edwin praised the heavy duty bag making machine. Now the sealing line is very nice and very stronger. Because most of time the mat...

> Loading bag making machine for Lebanon Customer

Today we loaded the film blowing machine, bottom sealing and cutting bag making machine and taiwan quality film blowing machine for Lebanon Customer.We have longest ...

English

English Français

Français Español

Español