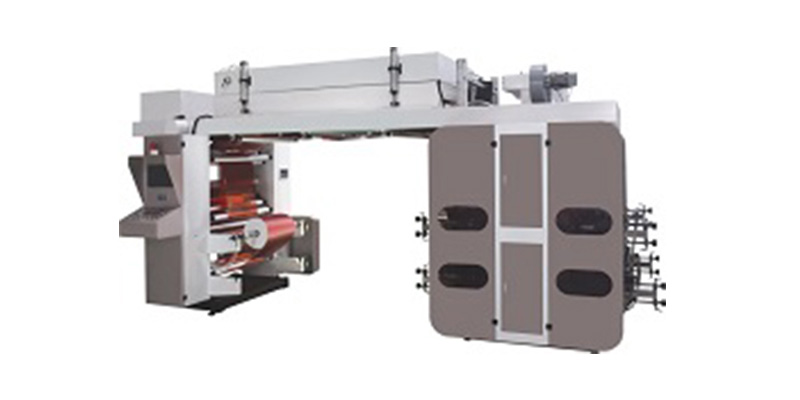

Mini Blown Film Machine New Type

Mini Blown Film Machine Features

● High-performance solution

Our mini film blowing machine can do 50kg/h. the film width can run from 100mm to 500mm width. We can control the film width according air supply. And the thickness of film can be adjusted also. It is very muti-functional.

● Cost-effective and user-friendly design

TPLAST mini film blowing machines are designed according to our customer requirements, providing cost-effective and user-friendly solutions for producing high-quality film products. The machine is designed with a simple control system, making it easily to operate and minimizing the possibility of errors during production.

Rugged and durable construction

The extruder, barrel, and screw are all made of high-quality alloy steel. After nitriding treatment and precision processing, they can get stronger hardness of surface of screw and barrel, which can run longer life.

Mini Blown Film Machine Parameter:

|

Model |

TP45 |

|

Diameter of screw |

Φ45 |

|

Max width of Film |

100-500mm |

|

Single-face Thickness of film |

0.008-0.10mm |

|

Output |

50kg/h |

|

L/D |

30:1 |

|

Power of main motor |

11kw |

|

Power of Traction main motor |

1.5kw |

|

Total Power |

20kw |

|

Outline diameter |

2300 x 2000 x 2300mm |

|

weight |

2000kg |

Controlling Box

Mini Film Blowing Machine Structure

Main Extruder

Mini Film Blowing Machine Main Parts Parameter and Pictures:

High Speed Die head: Taiwan design high speed die head:

1, #45 steel stronger

2, Surface treatment,which make film more transparent

3,bigger size than normal, which improve the output of machines

Stronger Structures: 4.5mm thickness Steel tube and 12mm thickness steel plate.

Screw: Copied from Taiwan Bimetal

1. Material of screw and barrel: 38CrMoAlA

2. Material Element Analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3. Hardness of tempering: HB260-290

4. Depth of nitriding: 0.4-0.7mm

5. Hardness of surface: HV900-1050

6. Roughnessof surface:Ra0.32

7. Bimetal screw: Bimetal layer on the screw thread

8. Hardness of bimetal layer: HRC58-62

9. Depth of bimetal layer: 2-3mm

10. Bimetal layer elements: Fe, Ni, Wc, B, C, Cu, ect

Main motor: Siemens Motor

1, Runing Speed: 1400rpm,

2 Motor power: , 380V, 3phase. Pwoer can be changed according yours

3, Motor Life: more 10 years.

Gearbox:

1, Fucntion: reduce the speed of transferring.

2, Speed rate: 10:1

3, Gear: Hard surface type, high quality.

4, Lubrication oil for transfering

5: Low noise and longer life

Heater: Ceramic heater fucntion:

1, Heating faster than stainless heater.

2, Life is longer to 5 years.

3, Keeping hot inside is longer than stainless, save power.

4, High quality ceramic and heating wire Inside.

Cover: Stainless cover:

1, Separate stainless cover to control heater better and save the power consuption.

2, Separate blower on stainless cover.

3, Nice outlook for stainess cover.

4, High speed blower to cool barrel.

Double Lip Air ring:

1, two lip to cool the film, it is faster than one lip.so it can improve the output of machine

Screen change: T Type

Electric parts: Omron Temperature controller:

1, Digital show

2, Accurate temperature controlling for 3 centigrade

3, Longer life to more 10 years

4, CHINT brand switch and breaker, best quality in China.

Controller box and LG inverter:

1, LG inveter to adjsut the speed of all motor, which can save the power consumption, protect the motor working.

2, LG inverter is longer time to more 10 years.

3, Easy to adjust the inverter.

Traction parts: Gusset copied from Taiwan

Gusset copied from Taiwan

1,Gusset parts is copy from taiwan, easy to adjust.

2, Wooden gusset parts is make

Traction motor:

1, 1.5kw,1400rpm running speed

2, Gearbox: 7.5:1 running speed

3, LG inverter controlling the motor running.Save power and speed adjusting.

Embossing roller:

1, Dot distance:2mm. We can design it according to yours

2, Controlled by air cylinder, which is easy to operate, no manual working.

Single Rewinder:

1, air shaft: save manual working,improve the working efficiency.

2, LG inverter controlling motor speed, save power consumption.

3, Inverter can be longer life and protect the motor running

4, counting meter to calculate the film roll length.

5, Alarm to remind worker change the rolls.

Whole machine: Nice design

For the screw and barrel, we design it according to Taiwan screw. There is double feeding in middle, which can improve the pressure and capacity. And there are channel design in the barrel. So it can improve the capacity of machines.

For the film blowing machine die head, the design following taiwan quality. It is bigger and higher, So it can keep hot power inside. It will save the power consumption. The mini film blowing machine die head is processed by Taiwan Center. After that, our worker polish the surface by manual, So it is very smoothly and more accurate. And this high speed die head can control the thickness of film more easily.

In conclusion

Our mini film blowing machines are a high-quality, cost-effective, and user-friendly solution for businesses looking to produce high-quality plastic film products. Mini film blowing machines are designed with Customer needs, providing efficient, durable, and customizable performance. We believe that our customer who invest in our mini film blowing machines will win significant improvements in their production capacity and overall efficiency. If you have any questions about our mini film blowing machine ,please feel free to contact us.

Tags:Mini Film Blowing Machine,Mini Blown Film Machine

> What is bag making machine?

A bag making machine is a machine that helps in the manufacturing different type bags. The T-shirt bag making machine is used for making the T-shirt bag. It can cut ...

> Side Sealing Bag Making Machine Features

Our Side sealing bag making machine have the following features:The unwinding part is controlled by the air cylinder which control the rubber roller, so that it is o...

> Loading Bag making machine and film blowing machine to Côte d'Ivoire

Today we loading two container to Côte d'Ivoire. The customer bough 4 sets film blowing machines, 4 sets bag making machine and 1 set heavy duty bag making machine a...

> Loading Bag making Machine to Colombia

We are happy to load the one set bottom sealing bag making machine, one set side sealing bag making machine and granulator to Colombia Customer today. It is very nic...

> Heavy Duty Bag Making Machine is praised by Mexico Customer.

Today our professional Customer Mr.Edwin praised the heavy duty bag making machine. Now the sealing line is very nice and very stronger. Because most of time the mat...

> Loading bag making machine for Lebanon Customer

Today we loaded the film blowing machine, bottom sealing and cutting bag making machine and taiwan quality film blowing machine for Lebanon Customer.We have longest ...

English

English Français

Français Español

Español