What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These machines are designed to efficiently manufacture bags with reinforced handles, typically made of polyethylene or other plastics.

1.What is a Patch Bag?

Patch bags are often used for shopping bags and other packaging applications that require a strong carrying capacity. The handle design of the Patch bag can make the bag easier to pick up and carry, especially when the bag is filled with heavier items. This design also improves the overall structural strength of the bag, making it more durable and reliable.

Patch bags are usually made of plastic materials such as HDPE (high-density polyethylene) and LDPE (low-density polyethylene). These materials have excellent physical and chemical properties and are suitable for packaging food, clothing and other goods.

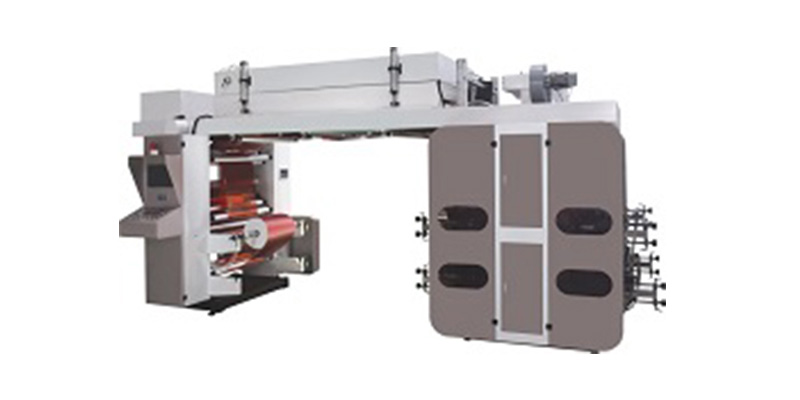

2. What is Patch Bag Making Machine?

The patch bag making machine is a highly automated equipment used to make various types of pouch bags. It has the following advantages:

1. Highly automated: controlled by a microcomputer and servo motor, it realizes the automated operation of the entire process of feeding, bottom sealing, cutting, punching and conveying.

2. Accurate positioning: the use of photoelectric tracking technology makes the positioning in the bag making process extremely accurate, greatly improving the product qualification rate.

3. Strong stability: the machine body has a simple structure and can automatically stop when there is no material or the bag is blocked, reducing the failure rate and loss in the production process.

4. Accurate temperature control: the temperature error is extremely small, and the bag making length can be freely adjusted according to needs to meet the production needs of various products.

Patch bag making machine core functions and modules:

1. Feeding system: The raw materials (such as plastic film) are sent to the machine for production processing with the help of the feeding device, which includes components such as tension adjustment equipment, rollers and motors.

2. Positioning system: Strictly control the movement trajectory and accurate position of the raw materials during the entire operation process, and often use photoelectric sensors or mechanical limiters to achieve precise positioning.

3. Cutting system: Finely cut the raw materials into bags of specific specifications, which mainly include cutting tools, power motors and corresponding control facilities.

4. Sealing system: Seal the cut materials to make the bagged items finally formed. At this stage, we need to use heating equipment, sealing rollers and pressure control equipment.

5. Receiving system: Responsible for the centralized collection of the finished bagged products for subsequent packaging and transportation. In this link, we will use related configurations such as receiving equipment, conveyor belts and counting equipment.

Patch bag making machine is suitable for packaging daily necessities such as clothing, shoes, gifts, documents, etc., and is also widely used in food, medical and other industries. Patch bag making machine improves production efficiency, reduces labor costs, and ensures the high quality and aesthetics of the product. By adjusting the machine parameters and configuration, one machine can be used for multiple purposes, reducing production costs and investment risks.

English

English Français

Français Español

Español