What is film blowing machine?What are the advantages of mini film blowing machine?

What is film blowing machine?

A film blowing machine involves one process used to make plastic film. Extruded tubular processing is most often used with polyethylene films but can be used with other polymers.

The film may be laminating film, shrink film, agricultural covering film, bags or film for textiles and clothing, and other packaging materials.

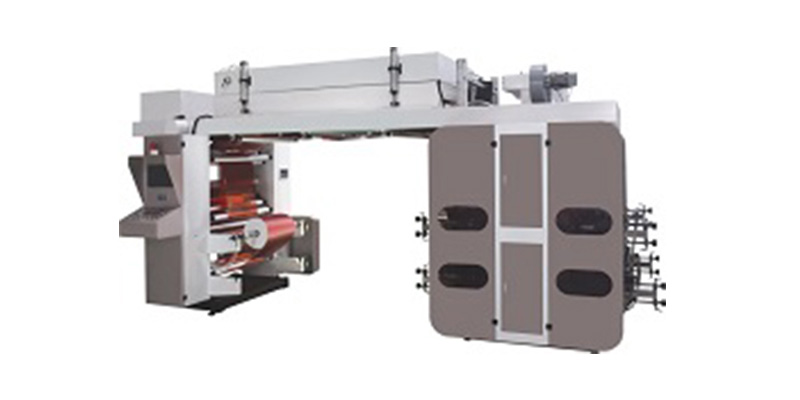

The film blowing machine parts include: screw and barrel, motor, inverter, heaters, die head, rewinder , controlling Box and Traction parts, The main motor we use like Germany's Siemens brand, improve speed regulation and save electricity. Quality assurance, The screw and material barrel made from a nitrogen-treated chromium-molybdenum-aluminum alloy like SCAM#645 ,38CrMoAlA...

At the beginning of the process, the polymer comes in the form of a pellet. it is heated and melted into a viscous liquid between rotating screws and barrels of the film blowing machine. This allows for the polymer to be fed through a die that shapes it in the form of a tube. This tube is then carefully inflated, so there is no risk of tearing, into a bubble by injecting it with air. The bubble is simultaneously being cooled in its interior, via a cooling system, and on the exterior surface, through the use of an air ring, to solidify the material.A set of collapsing frames or guides are then used to collapse the bubble into two, more defined, layers within closer proximity. Now that the layers are close, a series of nip rollers flatten the layers together to form a two-layered plastic film that is then wound onto a cylindrical roll for packaging purposes. This process may vary depending upon the specifications and models of the machines.

What are the advantages of mini film blowing machine?

Mini film blowing machines are very popular in the market, especially among beginners. It is a film blowing machine designed copy from Taiwan. Its mini film blowing machine than other film blowing machines, but it has complete functions and good configuration.Here is a detailed introduction to the advantages of a mini film blowing machine

Configuration advantages:

1.The cylinder and screw are both made of 645 # alloy, which has good hardness and strong corrosion resistance.

2. The screw is designed in imitation of Taiwan, with good plastic quality, which helps to improve production capacity.

3. Siemens motor long service life , inverter control design. cylinder control, saving labor.

4. Electric control brands: LS frequency converter, Omron temperature control, etc.

5.Mini film blowing machine is equipped with a meter counter, which can produce according to the number of meters you set, reducing manual measurement and improving work efficiency.

Application advantages:

1.Our mini film blowing machine suitable for blowing low density polyethylene (LDPE), high-density polyethylene (HDPE), linear low density polyethylene (LLDPE), and also suitable for biodegradable material .

2.We can use brand new materials or recycled materials. You can also use recycled materials and new materials to process together, of course, this combination has a ratio.

3. Mini film blowing machine widely used in the production of packaging bags such as food, clothing, garbage bags, vests, etc.

Capacity advantage:

1.Its product is 45-50KG/H(The production here is based on your materials), with a maximum film width of 500MM. Small machines can produce big output.

2. Mini film blowing machine have big advantages in installation ,its just use a small area and is easy to install. After receiving the machine, it can be directly powered on and used.

English

English Français

Français Español

Español