what is film blowing machine?

Film blowing machine is a key equipment in the plastic processing industry. It is mainly used to produce plastic film through film blowing extrusion process and is widely used in various industries. The following is a detailed introduction:

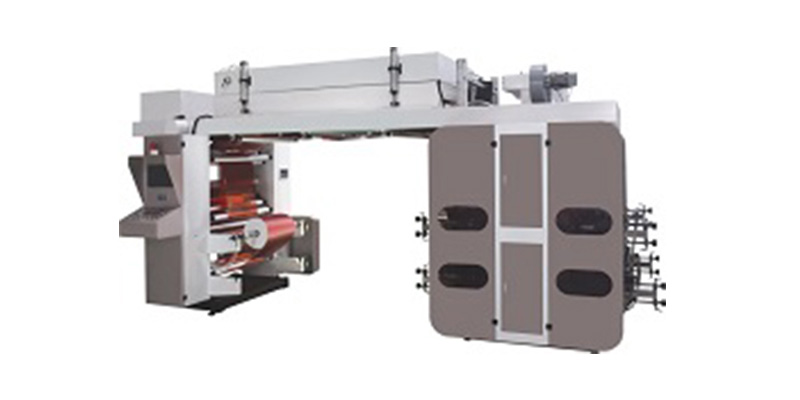

ABA Three Layer Film Machine Taiwan

Definition and Basic Concept

A film blowing machine, also known as a blown film extruder, is a machine that transforms plastic raw materials, such as polyethylene (PE), polypropylene (PP), and other thermoplastic resins, into continuous plastic films. The process is called blown film extrusion, which is one of the most common methods for manufacturing plastic films.

Working Principle

The working principle of a film blowing machine is based on the properties of thermoplastic materials. First, the plastic pellets are fed into the extruder barrel. Inside the barrel, the pellets are heated by electric heaters or other heating elements. As the temperature rises, the plastic pellets melt and become a viscous fluid.

The melted plastic is then pushed forward by a rotating screw within the extruder. This screw not only conveys the molten plastic but also applies pressure to it. The pressurized molten plastic is forced through a circular die, which is a ring - shaped opening at the end of the extruder. As the plastic exits the die, it forms a thin - walled tube.

At the same time, a stream of air is introduced into the center of the tube through a hole in the die. This internal air pressure causes the tube to expand radially, like a balloon being inflated. As the tube expands, the plastic film becomes thinner and is stretched both in the transverse (circumferential) and longitudinal directions.

The inflated tube, now a large - diameter plastic film bubble, continues to move upward. Along the way, it is cooled by air blown onto the outer surface of the bubble. Cooling is essential as it solidifies the plastic film, maintaining its shape and properties. Once the film is cooled and solidified, it is collapsed by a set of nip rolls. These rolls flatten the bubble into a double - layer film, which can then be further processed, such as being wound onto a roll for storage or subsequent use.

Main Components

-

Extruder: This is the heart of the film blowing machine. It consists of a barrel, a screw, and a heating system. The extruder melts the plastic pellets and pumps the molten plastic to the die.

-

Die: The die determines the initial diameter and thickness of the film. Different die designs can produce films with various widths and thicknesses.

-

Air Ring: The air ring is responsible for introducing the internal air pressure to expand the film tube and also for cooling the outer surface of the film.

-

Nip Rolls: These rolls collapse the blown - up film bubble and control the thickness of the final film by adjusting the pressure between them.

-

Winding Unit: The winding unit collects the flattened film and winds it onto a roll, ready for further use in packaging, agriculture, or other applications.

Applications

Film blowing machines are widely used in many industries. In the packaging industry, the films produced are used for wrapping food products, consumer goods, and industrial products. For example, food - grade PE films are used to package fresh produce, snacks, and frozen foods, ensuring product freshness and extending shelf life. In the agricultural sector, large - scale film blowing machines produce greenhouse films and mulch films. Greenhouse films help create a suitable micro - climate for plant growth, while mulch films are used to suppress weeds, conserve soil moisture, and regulate soil temperature. The construction industry also uses plastic films produced by film blowing machines for applications such as vapor barriers in buildings.

Advantages

The use of film blowing machines offers several advantages. Firstly, the blown - film extrusion process is highly efficient, capable of producing large quantities of plastic films in a relatively short time. Secondly, it allows for a wide range of film thicknesses and widths to be produced, meeting the diverse needs of different industries. Additionally, the films produced by film blowing machines have good mechanical properties, such as tensile strength and puncture resistance, which are essential for their applications.

In conclusion, the film blowing machine is an important piece of equipment in the plastics processing industry. Its ability to transform raw plastic materials into useful plastic films has made it an indispensable part of modern manufacturing, serving various industries and contributing to the development of daily - life products, industrial applications, and agricultural production.

English

English Français

Français Español

Español