Precautions for three-layer blown film machine

Tplast film blowing machine is suitable for manufacturing plastic film, nylon film and biodegradable film. The final product is used in shopping bags, food packaging and agriculture. The film quality is excellent and the strength is high. The Tplast machine adopts the screw and barrel designed in Taiwan, so the output is larger than that of the ordinary design screw. And the material of the screw is imported from Japan. This is very difficult and has a longer operating life.

The die material is imported from Japan and processed by Taiwan processing center. So it is very accurate and constant.

Overview:

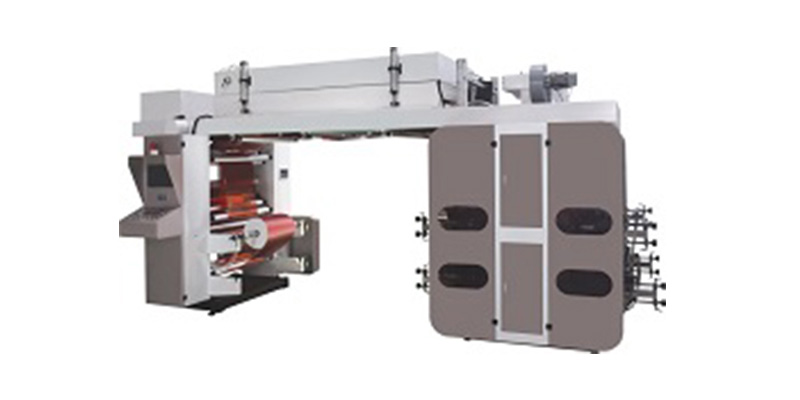

The three-layer blown film machine has the advantages of higher output, good product plasticization, low energy consumption, and easy operation. It completely solves the problems of film ruffles and winding heads, and brings product quality to a new level.

feature:

-

The horizontal type can be equipped with various functional components, such as length counting device, slitting device, cooling water pipe, film roll, waste collection device, etc.

-

The die head is a Raul type spiral mandrel, 360 degrees continuous and rotating.

-

The design of the screen changer is reasonable, convenient, reliable and safe to operate.

Precautions for use:

-

The operator cannot stand in front of the machine when operating the machine to avoid unnecessary accidental injury. When feeding, strictly prevent the hard objects that contain metal impurities and operating gadgets from falling into the barrel of the machine. In order to prevent injury to the involved machinery, it is strictly forbidden to wear gloves when operating the rotating machine.

-

Check and add the lubricating oil in the gearbox and air compressor, and check the lubrication of the mechanical transmission parts. Avoid dry operation damage the machine and make noise.

-

You must first check whether there is any disconnection or leakage of the power supply wiring when starting the operation; check whether the instrument is damaged or not. Before starting the machine, ensure that all components are safe and normal to avoid affecting production and causing accidents.

-

In the range of film forming conditions, increase the forming temperature, cooling air temperature and blowing ratio; then the turbidity of the film will increase and the gloss will decrease; vice versa.

-

When the die outlet is uniform and the material is uniform, you can wear gloves to slowly pull the tube blank, and at the same time, close the end of the tube blank, slightly open the air intake regulating valve, and put a small amount of compressed air into the center hole of the mandrel, and then be careful The ground guides the foam stabilizer and the herringbone, and penetrates the traction roller and guide roller until it is taken up (if embossing, it needs to pass the embossing roller)

-

The compressed air pressure of the inflated tube blank must be appropriate, not only can not break the tube blank, but also ensure the symmetry and stability of the membrane tube, and relatively ensure the quality of production.

-

You can use copper knives, rods or compressed air to clean the extruder and die, but do not damage the screw and the smooth surface of the screw.

Company Profile:

Ruian TPlast Machine Co., Ltd.: Located in the south of Zhejiang Province, it was established in 2001. We are a professional manufacturer of film blowing machines, bag making machines, printing machines and plastic recycling machines. We have an excellent R&D, design and sales team. Our engineers have more than ten years of experience in the plastics industry. We can design machines according to customer requirements.

Our markets are South America, Africa, the Middle East, the European Union and Southeast Asia. More than 98% of our products are exported to overseas markets. Export to the United States, Mexico, Greece, Croatia, Colombia, Dominican Republic, Nigeria, Ethiopia, South Africa, Saudi Arabia, Israel, etc.

English

English Français

Français Español

Español