How to adjust and clean the film head of a plastic film-blowing machine? Tplast will teach you

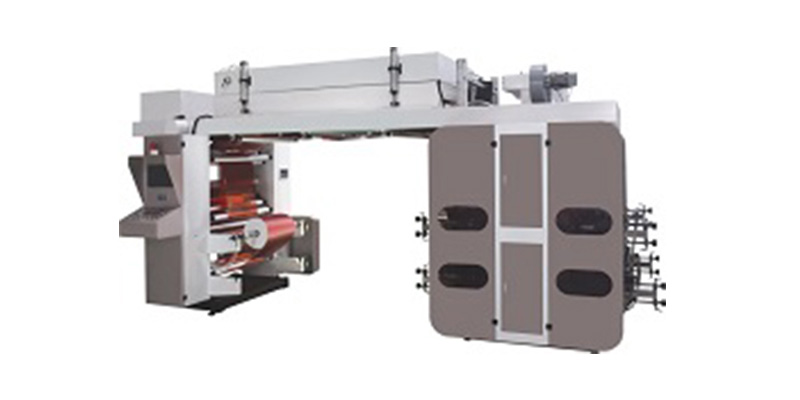

A film-blowing machine is a piece of equipment used to make films. It is formed by extruding molten plastic pellets or resin through an extruder and forming a continuous film after cooling and stretching.

Tplast shares with you how to adjust the film head of the plastic film-blowing machine

The mold is covered from top to bottom, that is, if it is thick, loosen the screws (tighten the thick side tightly). This is called a conforming die head. If the lower opening is large and the upper die is inserted into it, then the thin side should be loosened and the thick side should be tightened. This is called a reverse adjustment. The die head has 4 or 6 adjusting bolts, which are usually hexagonal ones. They can be adjusted on the upper edge of the die head. As for whether they are tight or loose, molds from different places of production are different. You will know after you start.

How to clean the die head of a plastic film blowing machine

Clean the touch head and spiral body. When cleaning, apply paraffin wax or methyl silicone oil, and then gently wipe the paste with 1000-grit sandpaper until it is clean. When changing the material, adjust the temperature appropriately according to the material properties (the temperature of the returned material is different from that of the pure material). After changing the screen, increase the extrusion volume to extrude the paste.

The key is that during the production process, it is often best to add a little methyl silicone oil to the hopper once a week, which can not only lubricate the screw die but also clear the mold.

4 functions of plastic film-blowing machine

(1) Packaging material production: The film blowing machine can produce transparent, translucent, or colored films, which can be used for packaging of food, medicine, daily necessities and other commodities.

(2) Plastic bag manufacturing: By passing the film through a paper cutter for cutting, folding, and sealing processes, plastic bags of various specifications can be produced, such as shopping bags, garbage bags, etc.

(3) Agricultural mulching film: The film-blowing machine can produce agricultural mulching film, which can protect crops from harsh weather conditions and pests, and improve the yield and quality of crops.

(4) Industrial packaging film: The film-blowing machine can also produce moisture-proof, dust-proof, tear-proof, and other functional films used for industrial product packaging, transportation, and storage.

Film-blowing machines have the characteristics of high production efficiency and simple operation and are widely used in various industries and fields.

English

English Français

Français Español

Español