Film extruder manufacturer talks about the difference between blown film and extruded film

What is the difference between blown and extruded film?

Film extruder manufacturers tell us that the difference between blown film and extruded film lies in the manufacturing process, film structure and application fields. The choice between blown film and extruded film depends on specific requirements. Film extruder manufacturers can provide further technical details and guidance based on individual needs.

Blown film and extruded film are both produced using film extruders, but they differ in their manufacturing processes and resulting properties. Here are the key differences between blown film and extruded film:

Manufacturing Process:

Blown film and extruded film are produced through different methods of film formation.

Blown Film: Blown film involves melting plastic resin and extruding it as a tubular bubble. The molten plastic is forced through an annular die, forming a cylindrical tube. Air is introduced through the center of the die, inflating the tube like a balloon. The inflated tube is then cooled and collapsed to form a flat film.

Extruded Film: Extruded film is produced by melting plastic resin and passing it through a flat die to form a continuous sheet of film. The molten plastic is extruded directly onto a chill roll or conveyor belt, where it is rapidly cooled and solidified into a flat film.

Film Structure:

Blown film and extruded film can have different structural characteristics.

Blown Film: Blown film typically has a circular or oval shape and exhibits a higher degree of orientation due to the stretching that occurs during the blowing process. This orientation can result in improved mechanical properties such as strength and puncture resistance.

Extruded Film: Extruded film has a uniform thickness across its width and length and tends to have a higher degree of planar orientation. It may have slightly lower mechanical properties compared to blown film, but it can offer better optical clarity and surface smoothness.

Applications:

Blown film and extruded film find applications in different industries and products.

Blown Film: Blown film is commonly used for applications requiring high toughness and flexibility, such as packaging films, bags, liners, and shrink wraps.

Extruded Film: Extruded film is often used for applications where optical clarity, surface finish, and printability are important, such as food packaging, labels, lamination films, and industrial films.

It's important to note that the choice between blown film and extruded film depends on specific requirements, such as desired properties, cost considerations, and end-use applications. Film extruder manufacturers can provide further technical details and guidance based on individual needs.

What is a film extruder?

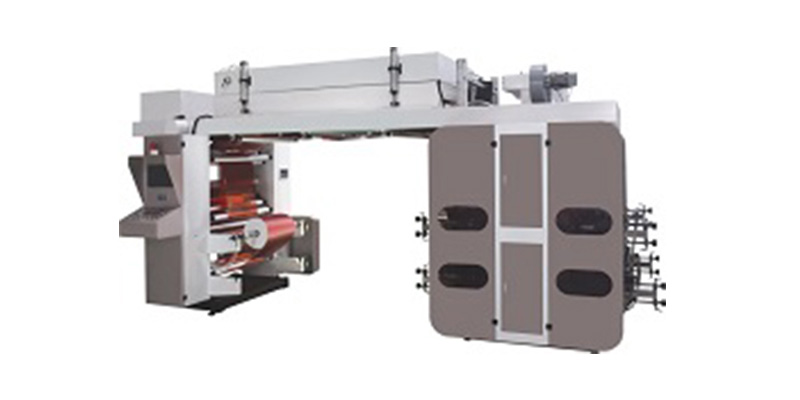

Film extruder is a machine used in the manufacturing process of plastic films. It works by melting plastic resin and then forcing it through a die to create a continuous sheet of plastic film. This film can be used for a variety of applications such as packaging, wrapping, and industrial purposes. The film extruder can be used to produce films of different thicknesses, widths, and materials depending on the specific requirements of the end product.

What is the purpose of an extruder?

The primary purpose of an extruder is to process raw materials, such as plastic, rubber, or food ingredients, by melting and shaping them into a specific form. Extruders are widely used in various industries for a range of applications due to their versatility and efficiency. Some common purposes of an extruder include:

★ Plastic Processing: Extruders are commonly used in the plastic industry to melt and shape raw plastic materials into films, sheets, tubes, pipes, and profiles for use in packaging, construction, automotive, and other applications.

★ Food Processing: In the food industry, extruders are used to produce various food products such as pasta, breakfast cereals, snacks, and pet food by cooking and shaping ingredients through extrusion.

★ Rubber and Polymer Processing: Extruders are used to process rubber and polymer materials for manufacturing products like seals, gaskets, hoses, and profiles.

★ Pharmaceutical and Chemical Industry: Extruders play a crucial role in the pharmaceutical and chemical industries for producing drug delivery systems, granules, pellets, and specialty chemicals.

★ Ceramics and Metal Extrusion: Extruders are also used in the ceramics and metal industry to shape materials into desired forms for manufacturing components and products.

Overall, extruders offer a cost-effective and efficient method for processing materials and producing a wide range of products with consistent quality and properties.

What are the disadvantages of blown film extrusion?

◆ Limited thickness control:

Blown film extrusion may have limitations in achieving precise thickness control, leading to variations in film thickness and potential quality issues.

◆ Lower production speeds:

Blown film extrusion typically operates at lower production speeds compared to other extrusion processes, which can result in lower productivity and higher production costs.

◆ Higher energy consumption:

Blown film extrusion requires higher energy consumption compared to other extrusion processes, leading to increased operating costs and environmental impact.

◆ Limited film width:

Blown film extrusion may have limitations in producing wide films, which can restrict the range of applications for the produced films.

◆ Film distortion:

The blowing process can sometimes lead to film distortion or uneven thickness distribution, affecting the overall quality and performance of the film.

◆ Limited material compatibility:

Some materials may not be suitable for blown film extrusion due to their properties or processing requirements, limiting the range of materials that can be used in this process.

English

English Français

Français Español

Español